THE TOP four Characteristics YOUR LASER CUTTING Provider VENDO

Wiki Article

Laser chopping is usually a manufacturing method applied to generate tailor made styles and models from the utilization of a large-powered laser beam. Laser chopping is routinely Utilized in the automotive, musical instrument and health care system industries since it is suitable for a variety of resources, which includes metallic, plastic, wood, glass, paper and gemstones, to produce intricate, exact and complex sections.

To supply these parts, laser slicing services suppliers make use of amongst three differing types of laser chopping: fusion cutting, oxidation reducing or scribing. Each individual method frequently produces a lot less contamination, Actual physical harm and waste, which contributes to content Price cost savings for that producer.

This blog put up is meant that may help you gain an improved comprehension of the laser slicing course of action so that you'll be well educated in deciding upon the right laser chopping company seller.

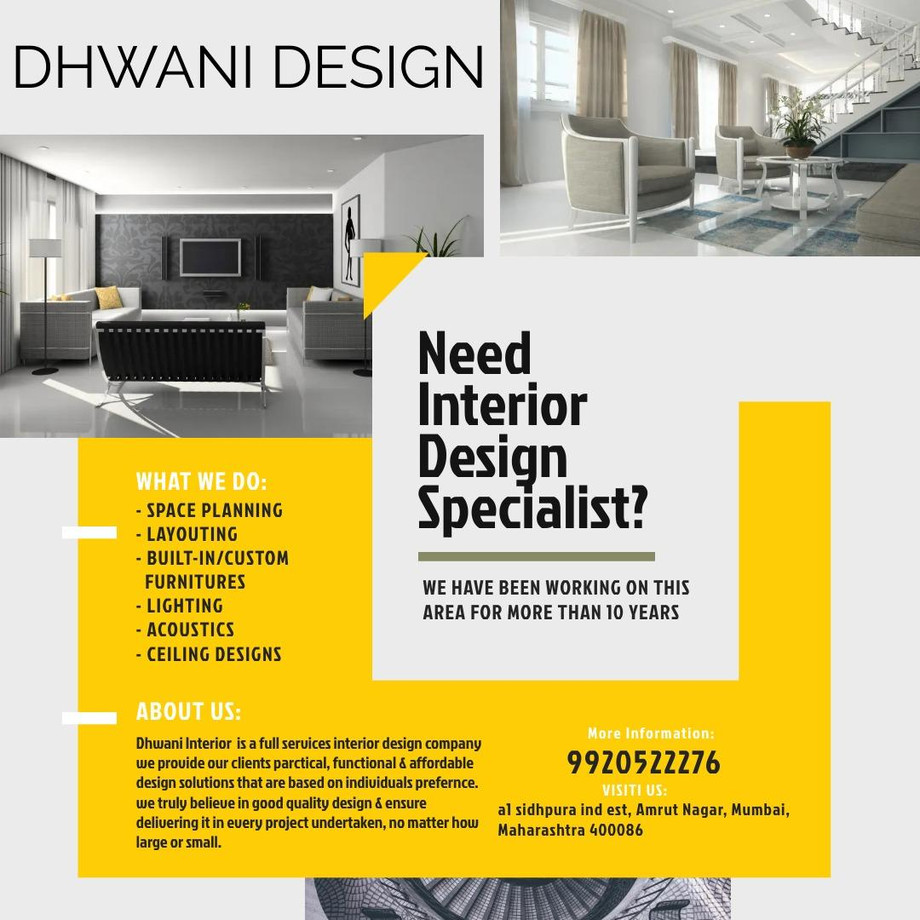

best Laser Cutting Service Provider in Mumbai Dhwani Design

The Laser Reducing Procedure and Equipment

Laser slicing is actually a thermal-centered, non-Speak to fabrication method suited to slicing metallic and non-steel resources. As opposed to mechanical chopping, which utilizes electricity-driven chopping machines, laser chopping uses a laser chopping device to create cuts, markings and engravings.

The Laser Reducing Process

Standard laser reducing consists of the the subsequent stages:

Beam technology: The laser beam is produced by way of spontaneous or stimulated emission.

Beam focusing: The beam enters through the nozzle that directs the world of effects.

Localized heating and melting: The beam is absorbed by the fabric that raises in inner Vitality and warmth era.

Substance ejection: As part of the heating and melting process, regions of the material are vaporized to create the desired Slice.

Beam motion: Movement and chopping are realized by way of reflective mirrors, laser head movement or workpiece manipulation.

Every single phase is critical towards the laser chopping procedure and manufacturing a precise Lower. With regards to the content and kind of Slice, laser reducing also employs inert or Lively assist gasses.

Sorts of Laser Chopping Machines

Though laser reducing machines vary in subtle ways from 1 model to the next, a laser reducing equipment is typically put in place to incorporate a laser resonator assembly, mirrors plus a laser chopping head, which includes a laser concentrating lens, a nozzle and a pressurized fuel assembly.

The different sorts of laser cutting machines are classified into gasoline, liquid and sound-condition lasers. The principle two kinds of lasers used by laser devices are CO2 and solid-condition lasers:

CO2 lasers: These are generally used to Lower non-metal supplies. Although laser technology has evolved to permit CO2 lasers to cut steel, they remain superior suited to reducing via supplies for instance rubber, leather-based or Wooden.

Stable-condition lasers: These are generally produced from crystal or fiber that make it possible for for high-driven metal cutting. Crystal lasers are amazingly functional in conditions of material slicing abilities. Nonetheless, they are typically costlier and also have shorter lifespans. Alternatively, fiber lasers are cheaper and more time lasting.

When exploring a laser reducing provider vendor, ensure to understand which kind of laser machines they have of their machinery established. As you could see, There are a variety of different equipment which might be far more suitable for certain tasks, and never all makers have every bit of machinery readily available.

The advantages of Laser Cutting

Laser cutting gives many pros—including adaptability, repeatability, Price tag-performance and speed—inside the manufacturing process of exact, higher-high-quality and flexible parts. By utilizing most effective procedures, your laser chopping support vendor really should provide the following characteristics:

a. Slicing Precision and Accuracy

Contrary to most common chopping devices, laser reducing equipment deliver a variety of cuts and designs that provide more precision and precision. Laser reducing devices are usually completely CNC managed, which suggests that they may have large repeatability in producing comprehensive, intricate pieces. The large-quality cuts produced by lasers normally do not want further more cleansing, managing or ending, which decreases the necessity for secondary procedures.

b. A lot less Content Contamination and Squander

For the reason that lasers use a focused beam that permits for narrower kerf widths, the quantity of substance taken off is minimized. With negligible thermal enter from localized heating, the warmth-impacted zones are minimized, which also decreases the thermal distortion. If thermal temperatures are way too substantial, the material may be broken, rendering the component worthless.

c. Decreased Servicing and Mend Fees

In comparison with other cutting equipment, upkeep costs for laser slicing tools are relatively small. In addition, laser cutting devices do not have to have modifying out different resources to accomplish distinct functions, which decreases both the products costs and lead time involving procedures. Lastly, laser parts experience significantly less tiredness for the reason that laser cutting is really a non-Get hold of system.

d. Higher Operator Safety

Laser cutting includes a lowered chance of operator injuries as it employs minor to no mechanical elements. Using a peaceful Procedure, laser slicing is a lot less distracting than louder processes. With significantly less conversation While using the device and less sounds, the overall place of work ecosystem is safer.

Select the Nicely-Geared up Laser Reducing Services Seller

By picking Dhwani Design as your laser chopping assistance vendor, you'll have a group While using the capabilities and equipment to operate with many different materials, meet up with complex necessities and supply the best prototype consistently, in time and within funds. Report this wiki page